PVC Decorative Film: Elevating Surfaces with Style and Functionality

In the world of modern interiors, surface aesthetics carry as much weight as structural integrity. Among the silent innovators transforming everyday materials is PVC decorative film—a versatile, visually rich solution that’s revolutionizing the way we think about surface finishes.

From cabinetry to wall panels, from doors to consumer electronics, this high-performance material seamlessly blends beauty with resilience. But what exactly makes PVC decorative film such a compelling choice?

A Sophisticated Surface Solution

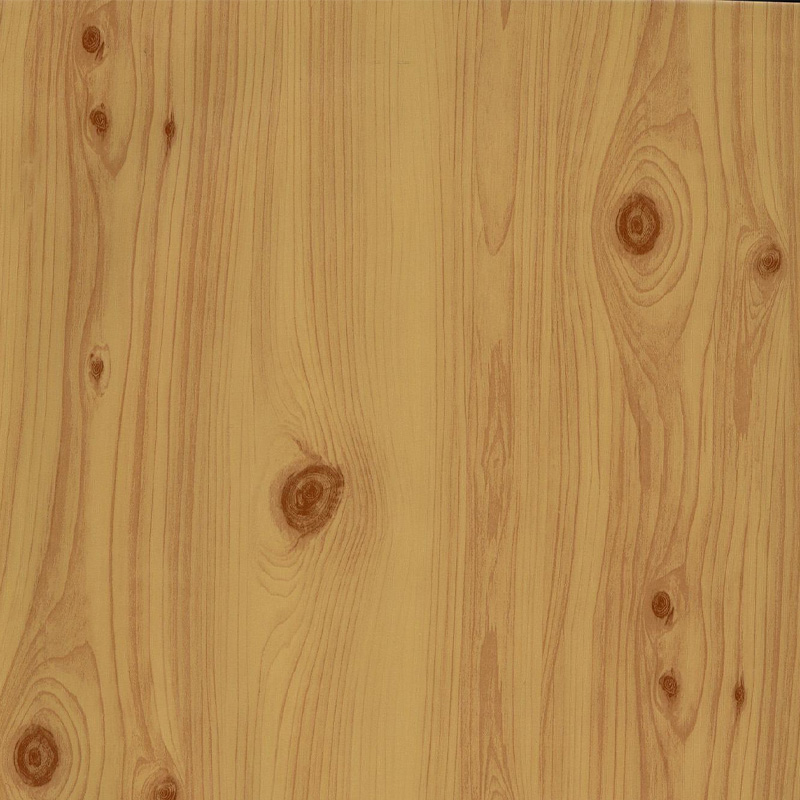

At its core, PVC decorative film is a flexible, printable thermoplastic sheeting engineered to mimic the look and texture of more expensive, often fragile materials like wood, marble, metal, or fabric. It is designed for lamination onto various substrates—most commonly MDF, HDF, particle board, and even metal or glass.

The end result? A sleek, refined surface that exudes character and depth without compromising durability or increasing cost. Unlike paint or veneers, PVC films offer consistency, quicker application, and a vastly wider range of design possibilities.

A Marriage of Aesthetics and Performance

The strength of PVC decorative film lies in its ability to satisfy both the eye and the environment in which it exists. Engineered to resist moisture, UV radiation, abrasions, and general wear, these films are more than just visually appealing—they are robust, enduring layers that protect what lies beneath.

The textures are tactile. Think soft-touch matte, high-gloss brilliance, embossed grains, and brushed metallic finishes. Whether you’re crafting minimalist cabinetry or ornate retail displays, there’s a PVC film tailored to the visual narrative you’re pursuing.

Moreover, the print fidelity is exceptional. Thanks to advanced gravure and digital printing technologies, patterns—from natural oak to abstract geometrics—are rendered with near-photographic accuracy.

Seamless Application, Lasting Impressions

Another critical advantage lies in its application process. PVC decorative films are engineered for thermoforming, membrane pressing, or flat lamination, depending on the intended surface and design complexity. This adaptability allows for seamless wrapping around curves, edges, and recesses, creating uninterrupted designs that feel tailor-made.

More importantly, the application process is clean. No dust, no overspray, no drying time. The result is a faster turnaround with fewer variables and less waste—especially appealing for manufacturers operating on tight production timelines.

Sustainability with Substance

Today’s eco-conscious market demands more than just style. PVC decorative film is rising to meet that challenge. Many manufacturers now offer films free of phthalates and heavy metals, with low VOC emissions that align with stringent environmental standards. Some even offer recyclable or partially bio-based options, making sustainability a natural part of the design process—not an afterthought.

Design Freedom Without Boundaries

Interior designers and architects increasingly turn to PVC decorative films to unlock creativity without constraint. Want the look of weathered barnwood without the unpredictability of real timber? Need a metallic finish without the weight or cost of actual metal? PVC film enables such illusions with startling realism, offering freedom that traditional materials simply cannot match.

From high-end residential interiors to bustling commercial spaces, the application of decorative PVC films is as limitless as imagination permits.

PVC decorative film is not just a surface covering—it’s a design tool, a protective shield, and a cost-effective alternative rolled into one. It empowers manufacturers, designers, and end-users alike to create spaces and products that marry elegance with endurance.

In a market where form must meet function—and where time, cost, and environmental impact are constant considerations—PVC decorative film emerges not as a compromise, but as a clear, confident choice.

English

English русский

русский Español

Español عربى

عربى bahasa Indonesia

bahasa Indonesia